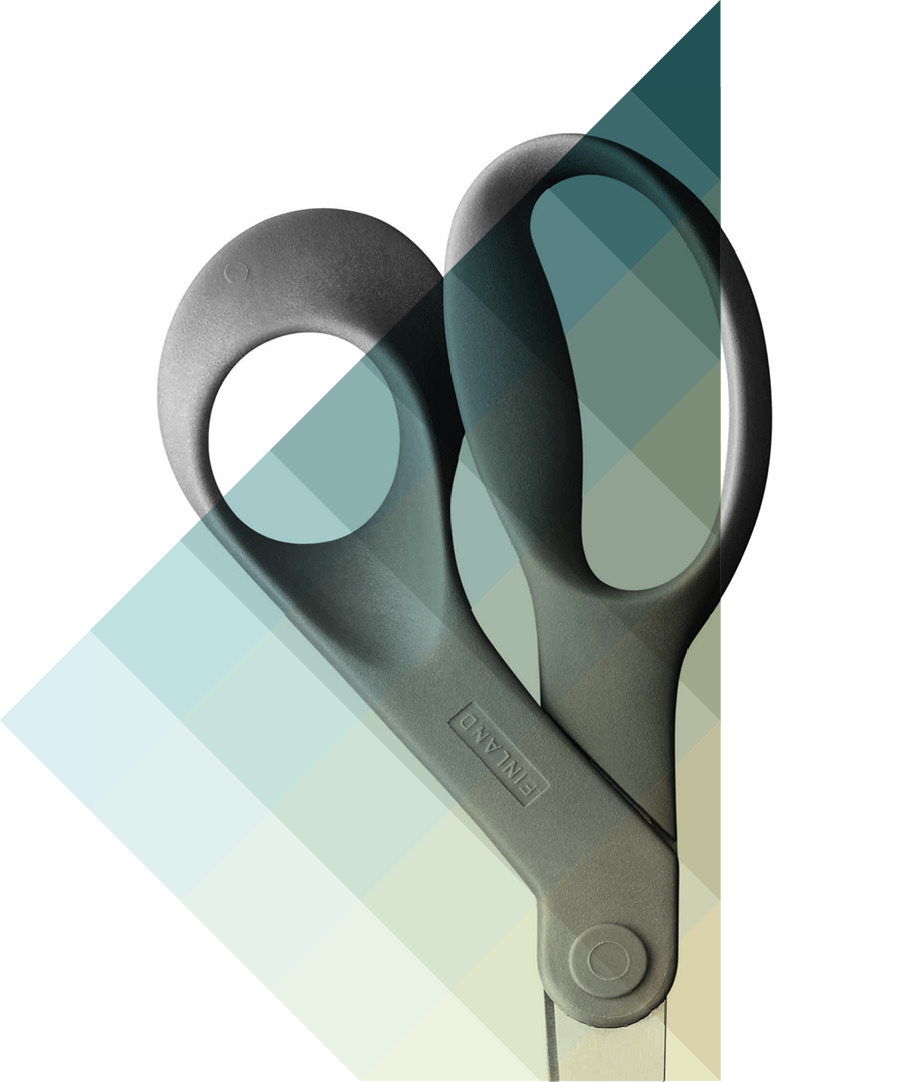

Fiskars launched a new version of its classic scissors in 2020. The new scissors are fully recyclable. They are 80% recycled material and 13% cellulose fiber. To recycle the scissors, the user must send them to the Fiskars Billnäs factory. There, the scissors are taken apart and the materials are sent to subcontractors for refinement. The renewed materials are then brough back to Fiskars and used to make new recycled scissors.

- What materials could you replace with recyclable ones in your product?

- How could you use recyclable materials in production?

- How could you make it easy to recycle a product?

More information (in Finnish only): https://www.fiskars.com/fi-fi/sakset/tuotteet/kierratyssakset

Aalto DF

Aalto DF