You may have heard of this equation: growing populations with higher demands and incomes require more natural resources. This has led us to the situation where human-made things, such as consumables, cars, and infrastructure, now exceed all living species’ weight on Earth. Moreover, the volume of new material manufactured every week equals the total weight of our planet’s human population. (Stokstad, 2020). Quite shocking, right? Therefore, both technological- and material-related innovations are needed in all areas to reduce our enormous environmental footprint. How about makerspaces? How this material-related challenge could be tackled while prototyping?

A recent study conducted in six different university-based makerspaces revealed that makerspaces are interested in using both bio- and upcycled materials but many of them have not tried them. The potential of these materials and their value in the future have been recognized, but there appears to be a lack of actual material experiments. Thus, we decided to give it a try and ended up experimenting with makerspaces’ waste streams to create new material for prototyping purposes. Let’s find out how did it go.

Wood based materials was clearly the largest waste stream with potential for reuse. Thus, different kinds of wood chips and sawdust were selected as a starting point. As one of the main targets of this study was to use as high share of waste materials as possible, recycled paper was selected to act as a filler material. Both of these materials create relatively steady waste streams and are pretty easily available in many makerspaces. In addition to sawdust and recycled paper, wheat flour and corn starch were used due to their binding, viscosity forming, and adhering related properties.

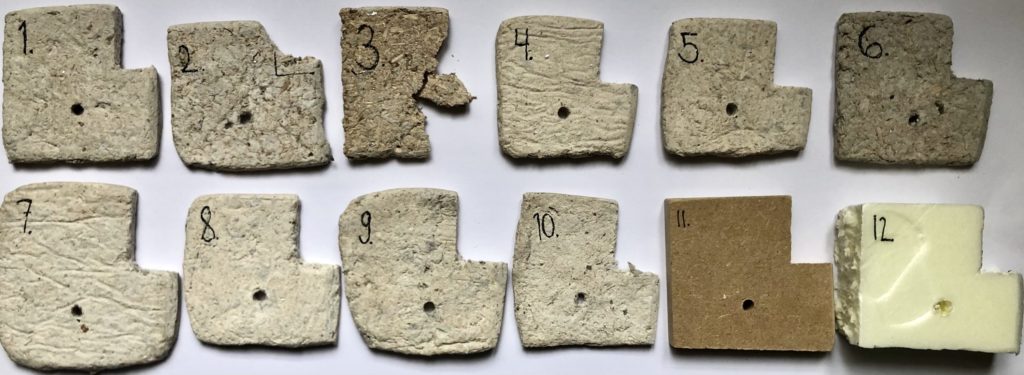

After preparing 18 different material test batches with varying levels of different ingredients, and conducting machinability tests (with saw, drill, file and sandpaper) with case material, we found that the studied material potentially could be used for prototyping. Especially if the low-fidelity prototyping phase is considered. Moreover, the case material seems to have the required material properties that enable its use with different prototyping tools and may be even as workable as the comparison material MDF. Additionally, in contrast to MDF, the case material can be molded and used for varying forms and shapes, which may be one of the most remarkable advantages of this material. Below you can see some examples from what kind of models we created, and how the material can be both molded and worked with different tools.

However, while the material’s functionality has been demonstrated, it may not yet replace any current prototyping materials, such as polystyrene or MDF or polystyrene. To use the studied material on a wider scale, the total net impact should be considered more in detail. Therefore, used resources, such as time, inputs, and energy, should be investigated further compared to the achieved benefits. Additionally, some issues, such as possible material cracking and rather long drying time, still remain that need to be addressed.

In summary, the project demonstrated that there indeed are potential applications for waste streams identified from makerspaces. Let it be new prototyping material, or something else, innovative- and renewable materials hold a significant potential to satisfy the accelerating demands towards valuable natural resources in our society.

References

Stokstad, E. (2020). Human ‘stuff’ now outweighs all life on Earth. Science. https://doi.org/10.1126/science.abg0874

Tanja Honkala 14.5.2021

Aalto University / Aalto Design Factory

Aalto DF

Aalto DF