Today, makerspaces are becoming increasingly popular on university campuses by providing an opportunity to design, fix, and prototype physical artifacts to a growing number of makers. This quick increase in the maker initiatives has also brought up the discussion around environmental impacts of the makerspaces. On the one hand, makerspaces can potentially act as knowledge centers and emphasize, for example, local production. However, on the other hand, the decreasing operating costs of, for example, 3D printing can lead to increasing amounts of failed prints and plastic waste. This leads us to the question of what is then the current situation in university-based makerspaces and how the fit of this movement into the context of the circular economy can be enhanced? Let’s see what we can learn.

A recent study conducted in six different university-based makerspaces revealed that many circular themes can already be linked to the makerspace and their culture of making. In general, a wide range of different solutions related to recycling, reusing and, for example, sustainable material use are applied. However, while a wide variety of different forms of actions have been taken to increase the material circularity, many challenges still remain ranging from the lack of cooperation to materials-related knowledge gap. The following takeaways from the study may help to clarify the challenges, and overcome the potential obstacles on the journey towards circular makerspaces:

Implementation of a wide range of methods

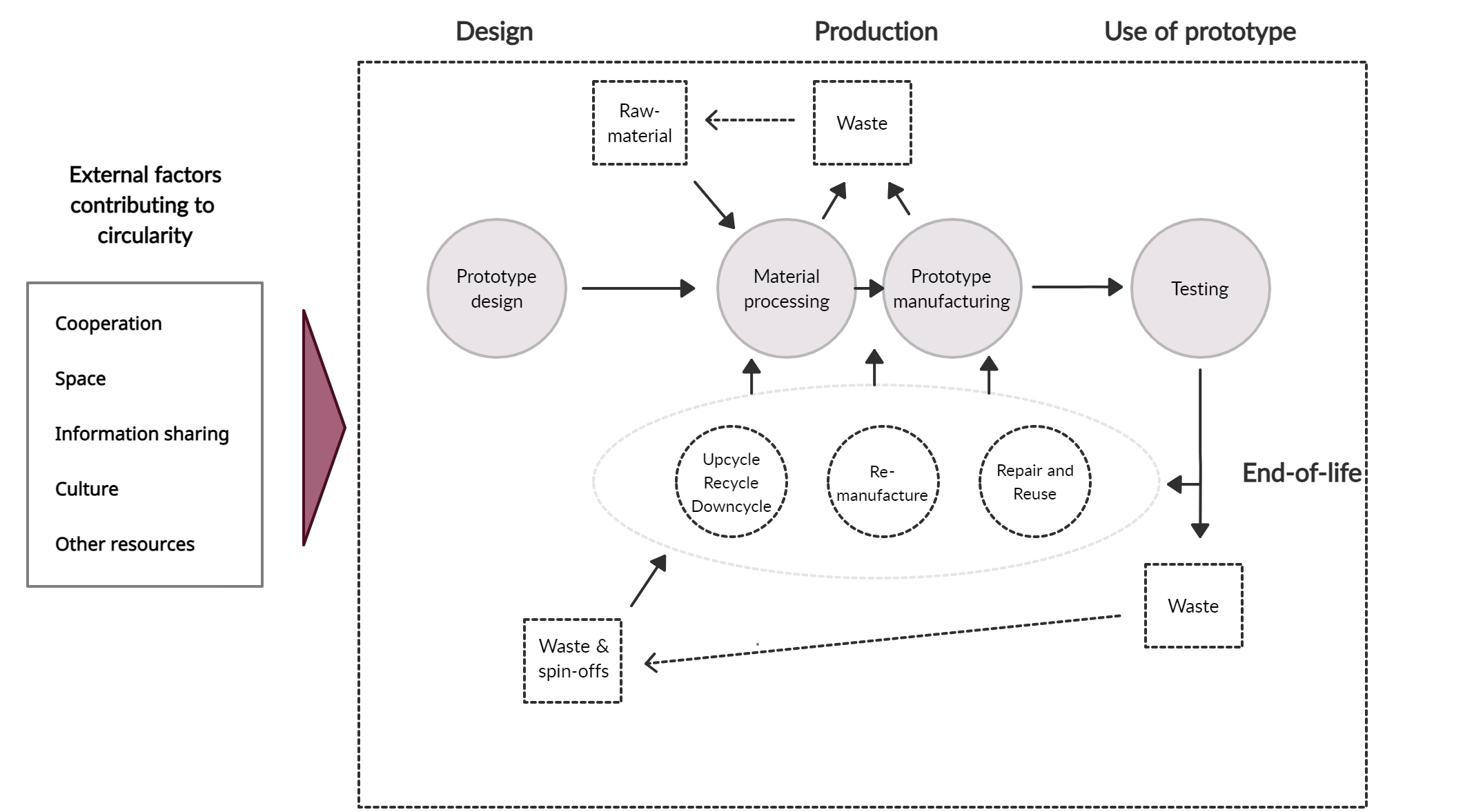

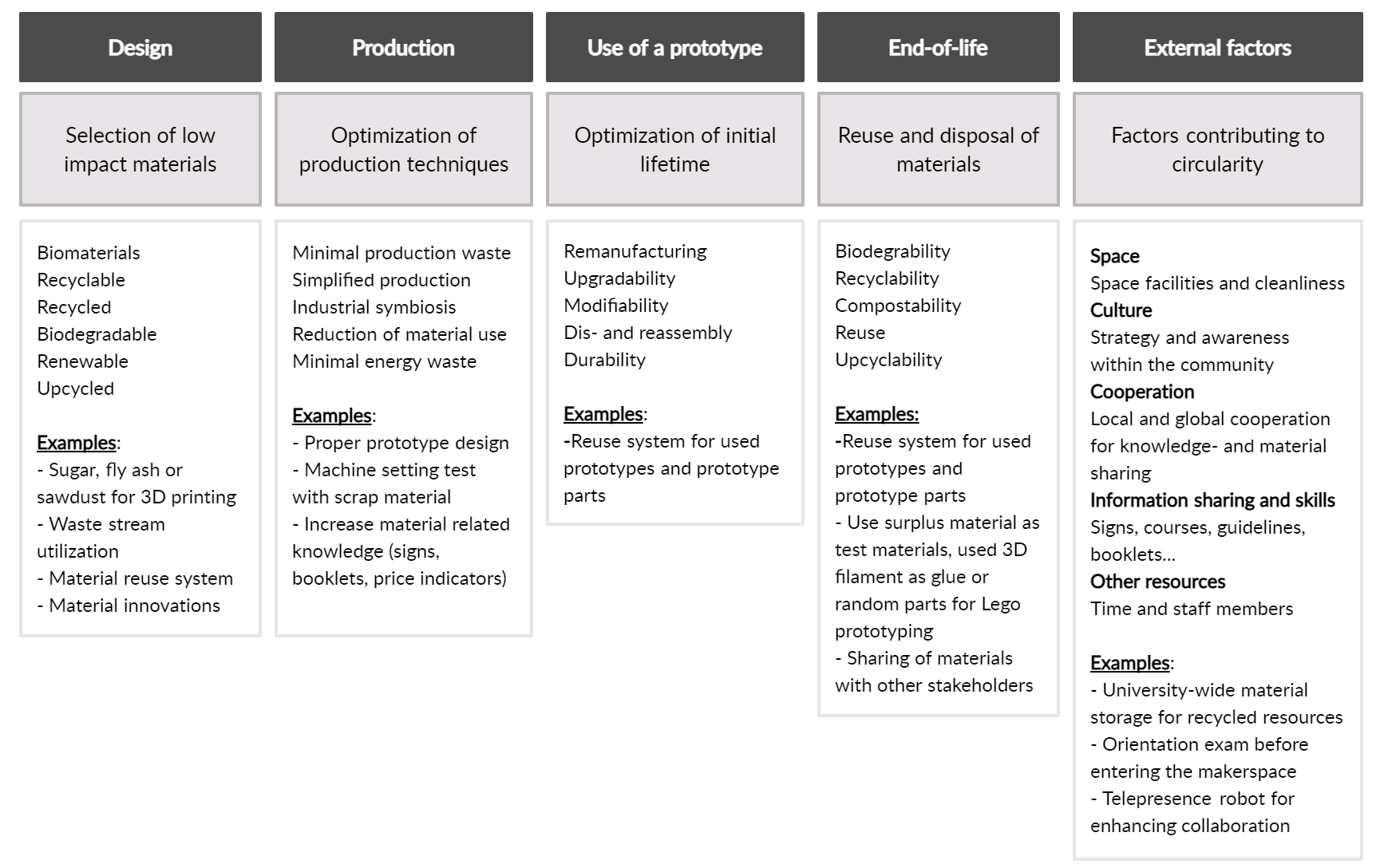

The overall scale of actions taken to increase the material circularity is wider than expected. According to the study, the mix of methods used for fostering the material circularity can vary from small signs to more comprehensive material recycling systems, and each of the interviewed makerspace seems to have their own combination of actions. Identified actions can be grouped under five separate groups: Design, Production, Use of a prototype, End-of-Life, and External factors. Thus, a holistic approach for increasing material circularity should be applied, as the range of potential methods is broad.

Scattered material scope

When it comes to identified differences between interviewed makerspaces, the orientation towards bio- or recycled materials is one of the prominent ones. As in line with the previous literature, the study revealed that different sustainable materials are, to some extent, being examined, but yet, it is not a part of the normal day-to-day operations. Therefore, new and innovative prototyping materials could be the next potential area to explore more thoroughly within this context by improving both material-related knowledge, and sustainable materials use.

Additionally, results indicate that the materials intelligence-related knowledge gap exists in makerspaces, and more guidelines are needed in that area. Especially after materials have been already used, identifying a particular material becomes challenging. This also creates potential obstacles for recycling. As a practical suggestion, the most common prototyping materials and their value could be introduced to new makers before starting any prototyping processes. Moreover, signs indicating the value of material, in terms of cost or, for example, used natural resources, could be utilized.

Underlined role of cooperation

Cooperation and partnerships, both internally and externally, seem to have a remarkable role in the equation and foster the shift towards more circular prototyping practices. Whereas some makerspaces were already

utilizing different collaborations as a means of knowledge- and material sharing, others saw that as an essential area of improvement.

Furthermore, while enhancing the information sharing between different stakeholders, cooperation and partnerships can also directly foster material circularity. As the study revealed, different forms of collaboration have been utilized to foster material sharing within communities, and the methods may vary from detecting local waste streams with partners to offering surplus resources for nearby startups.

Thus, it can be concluded that different kinds of forms of cooperation have both direct- and indirect effects on material circularity. However, the full potential of cooperation has not yet been utilized.

As a summary, the study characterizes current methods used for increasing material circularity, collects challenges faced in makerspaces, and finally suggests a framework for supportive actions. Additionally, it demonstrates how material circularity can be increased in action. An upcoming post will give a glimpse to this material case study that introduced a potential application for waste streams identified from makerspaces. Stay tuned!

Tanja Honkala 15.4.2021

Aalto University / Aalto Design Factory

Aalto DF

Aalto DF